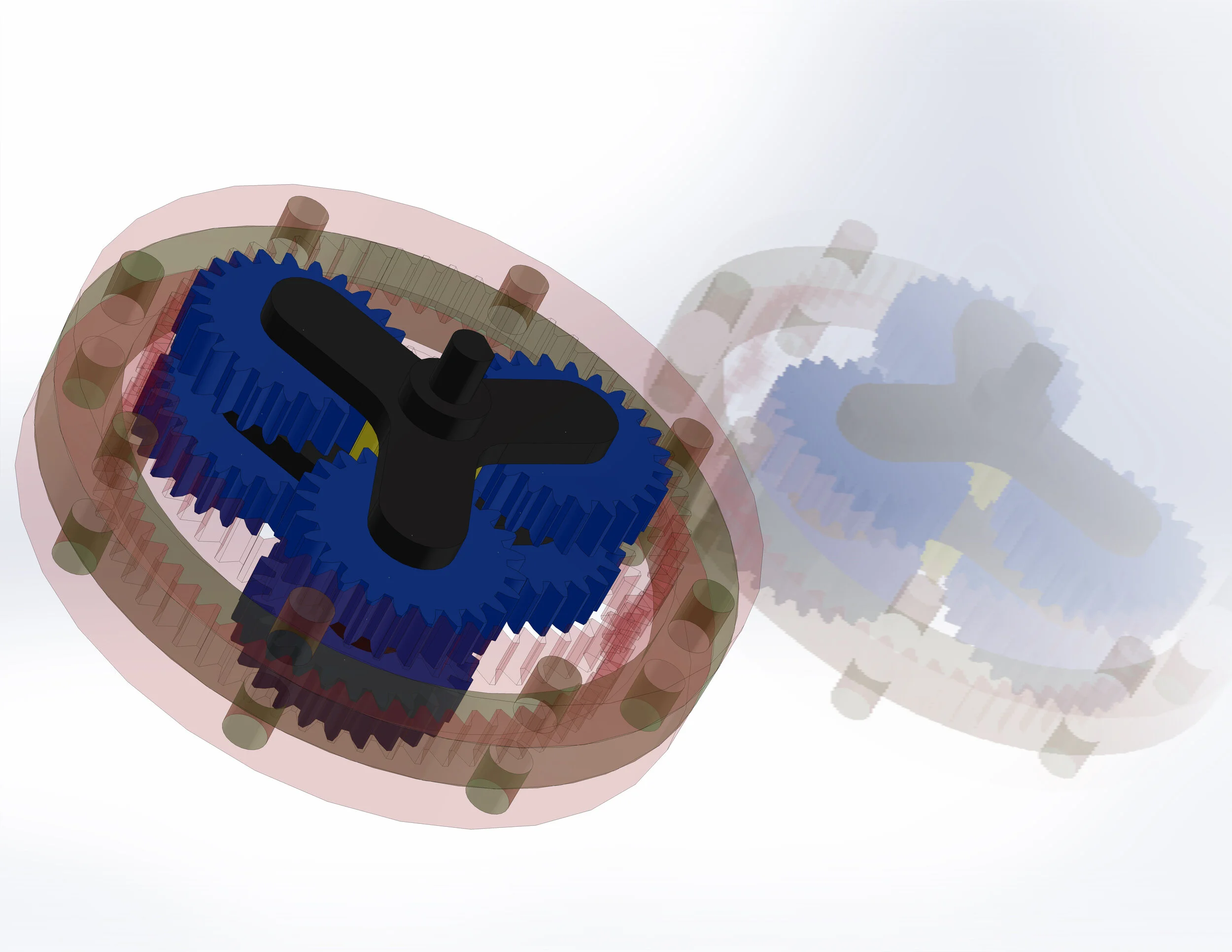

Extruder Gear System.

Goals

Design and manufacture a stackable planetary gear system to replace the current drivetrain on the Society of Engineering Mechanics' chocolate 3D printer

Have an ultimate gear ratio of 9:1

Design to be driven by a Nema 17 stepper motor

Contributions

Fully designed and manufactured myself using SolidWorks, Fusion360, FDM printing, and acrylic laser cutting

Final prototype has a 3:1 gear ratio per tier, so two tiers result in the desired 9:1 ratio

Tested and iterated, resulting in a design with much less friction and 1/4" thinner layers

Assembled the entire drivetrain, mounting my gears to the printer and successfully running prints

Results

A modular, stacking system of planetary gears with an exponential increase in gear ratio per additional tier

Currently installed on the chocolate 3d printer, successfully driving the extruder as intended

For added fun, I manufactured a stack of 13 gears, resulting in a 1,590,000:1 gear ratio